FAQs:

1. What does “Kitchen Cabinet Design from 2D to 3D” actually mean?

It means we take your 2D floor plans and measurements and turn them into a clear, visual Kitchen Cabinet Design that you can see and understand in 3D. You’ll see cabinet positions, heights, colors, materials, appliances and lighting before production starts.

2. Why is 3D visualization important for Kitchen Cabinet Design?

3D visualizations make Kitchen Cabinet Design easier to understand for everyone—developers, builders, designers, and end users. Instead of guessing from technical drawings, you can see:

How tall units and wall cabinets look in the room

How colors, countertops, and backsplashes work together

Walkways, island size, and overall proportion

This reduces misunderstanding and redesign later.

3. What information do you need to start the 2D Kitchen Cabinet Design?

To begin, we usually ask for:

2D floor plan with dimensions (PDF, DWG, or clear image)

Ceiling height and window/door positions

Appliance sizes (fridge, oven, cooktop, hood, dishwasher)

Preferred Kitchen Cabinet Design style (modern, classic, luxury, minimalist)

Target market and budget level

The more accurate the 2D information, the more accurate the 3D result.

4. How do you go from a basic 2D plan to a complete 3D Kitchen Cabinet Design?

Our typical steps:

Analyze the 2D layout and confirm measurements/openings.

Plan the Kitchen Cabinet Design layout (L-shape, U-shape, island, galley, etc.).

Place cabinets, drawers, tall units, and appliances according to ergonomics.

Apply materials, finishes, handles, and countertop details.

Generate 3D renderings and perspective views for your review.

You see both the technical side and the visual effect.

5. How accurate are the 3D visuals compared to the final cabinets?

Our 3D visuals are based on real cabinet modules, real dimensions, and actual materials used in production. While lighting and décor may differ slightly on site, the Kitchen Cabinet Design layout, cabinet sizes, and basic appearance will match the confirmed drawings and spec sheet.

6. Can I request changes after seeing the 3D Kitchen Cabinet Design?

Yes. That’s one of the biggest advantages. After you see the 3D:

You can adjust cabinet positions (e.g., move tall units, change island size).

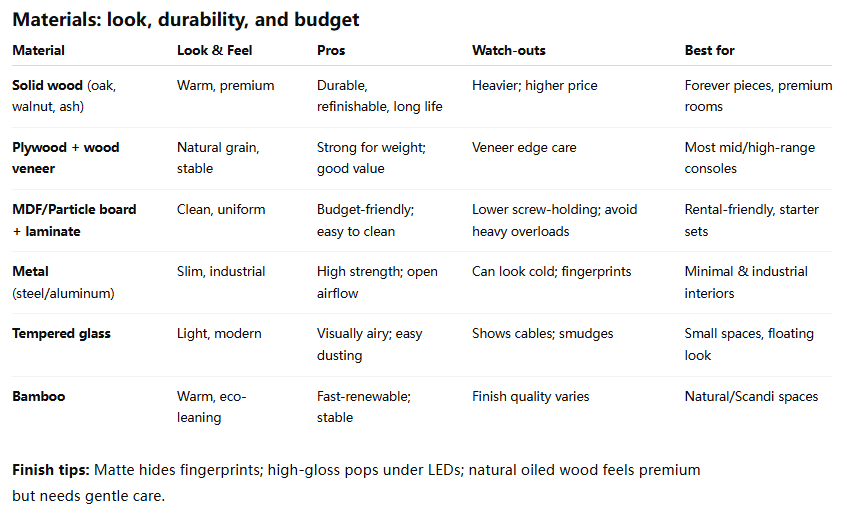

You can test different Kitchen Cabinet Design colors and finishes.

You can upgrade/downgrade materials to fit your budget.

We revise the 2D and 3D until you are satisfied, then move to final confirmation.

7. How does this 2D-to-3D process help for overseas or large projects?

For overseas developers, builders and wholesalers, face-to-face meetings are not always possible. Clear Kitchen Cabinet Design communication via 2D + 3D helps to:

Align your team and our factory, even in different time zones

Show your clients or buyers realistic visuals for faster decisions

Reduce risk of errors when producing for hundreds of units or multiple buildings

Everything is clearly documented before production.

8. How do you coordinate Kitchen Cabinet Design with appliances and MEP points?

During design, we:

Reserve correct spaces for each appliance based on supplied specs

Check sink, tap, hob and oven positions against plumbing and electrical points

Adjust cabinet sizes and fillers so Kitchen Cabinet Design works with real site conditions

This minimizes clashes between cabinets, appliances, and MEP on site.

9. Can you provide multiple design options from the same 2D layout?

Yes. From one 2D plan, we can create different Kitchen Cabinet Design options, for example:

Option A: More storage and tall cabinets

Option B: Bigger island and more seating

Option C: Different color and finish combinations

This helps you compare function, style, and cost before choosing the final direction.

10. How long does it usually take to receive 2D and 3D Kitchen Cabinet Design proposals?

Timing depends on project size and complexity. For a standard kitchen, after receiving complete information, we can usually provide initial Kitchen Cabinet Design 2D+3D proposals within a relatively short design cycle. Larger projects with multiple room types will be scheduled in batches.

11. Can AIS 3D visuals be used in my marketing or sales presentations?

Yes. Many clients use Kitchen Cabinet Design 3D renderings:

In brochures and online listings

For project presentations and show units

To help buyers visualize their future homes

We design with both technical accuracy and visual appeal in mind, so your marketing team can benefit directly.

12. How do you ensure the final production matches the approved 2D and 3D Kitchen Cabinet Design?

Once you confirm the design, AIS:

Locks all dimensions and details into shop drawings and cutting lists

Links the Kitchen Cabinet Design to our ERP/production system

Uses QC checks during cutting, drilling, edge-banding, and packing

Numbers each cabinet according to the final layout

This closed loop makes sure the finished cabinets on site follow the approved 2D and 3D design.

13. What is my role in the 2D-to-3D Kitchen Cabinet Design communication?

Your main responsibilities are to:

Provide accurate site information and requirements

Give timely feedback on layouts, colors, and Kitchen Cabinet Design details

Confirm the final drawings and materials before production

AIS handles the professional design and technical work; you make the final decisions that fit your project and market.