Total Cabinetry And Joinery Solution

ENG

In modern kitchen construction, MDF kitchen cabinets have become one of the most popular choices among developers and builders who value affordability, design flexibility, and a premium painted finish. MDF — short for Medium-Density Fiberboard — offers a smooth, uniform surface that’s ideal for painting, laminating, or lacquering, making it a go-to material for large residential and commercial kitchen projects.

This guide covers everything you need to know about MDF kitchen cabinets — including their structure, benefits, limitations, cost, and best applications for developers and builders.

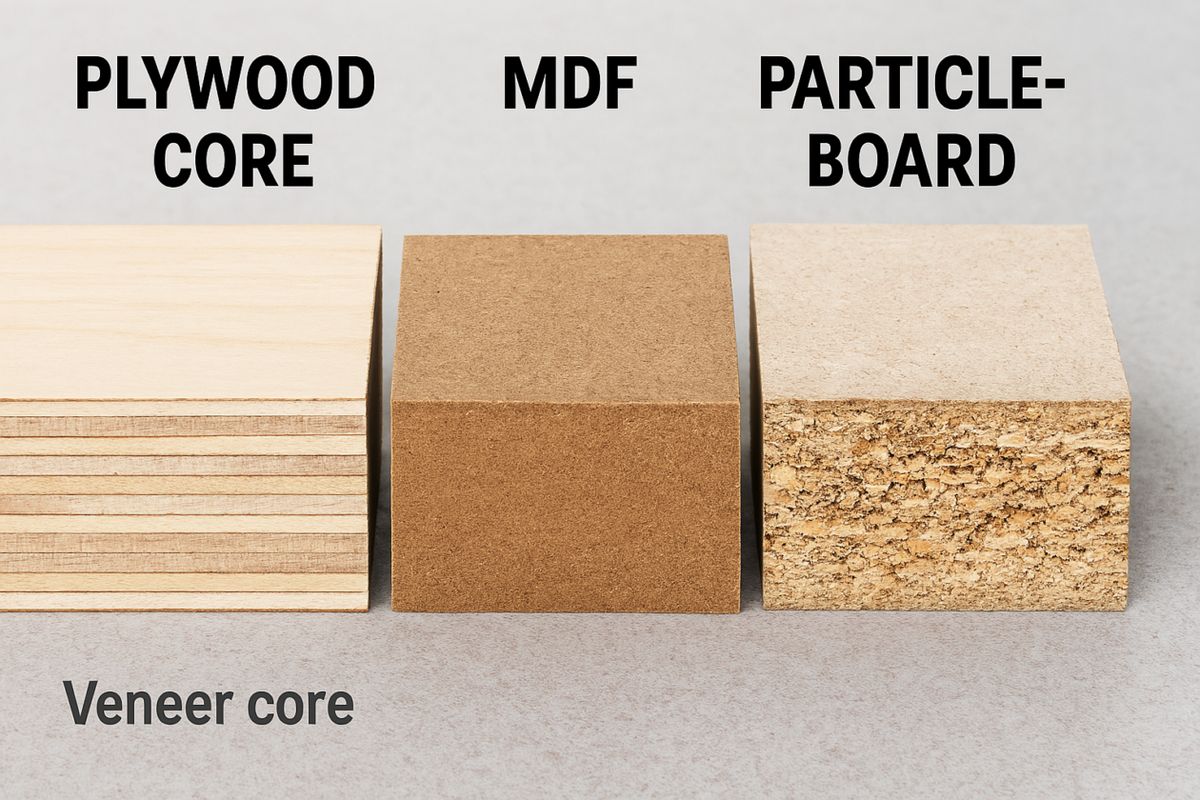

MDF (Medium-Density Fiberboard) is an engineered wood product made by compressing wood fibers, resin, and wax under high pressure and temperature.

It’s denser than particleboard and smoother than natural wood, which allows for precise milling and flawless finishes.

Key Characteristics:

Smooth and uniform surface with no visible grain

Ideal for painted or lacquered finishes

Stable and less prone to warping than solid wood

Cost-effective and easy to machine for decorative profiles

Because of its density and fine texture, MDF is widely used for cabinet doors, panels, and decorative moldings that require detailed designs.

For developers managing multi-unit projects, MDF offers the perfect balance between visual appeal, consistency, and cost efficiency.

Top reasons why MDF is ideal for large projects:

Cost-Effective Production – MDF costs significantly less than solid wood or plywood, making it perfect for large-scale orders.

Design Flexibility – It can be easily milled into detailed shapes, allowing for Shaker, flat, or modern slab door styles.

Consistent Quality – Each panel maintains the same density and texture, ensuring a uniform appearance across hundreds of units.

Perfect Finish Surface – The smooth surface is excellent for painted or lacquered designs, commonly seen in modern and minimalist kitchens.

Feature | MDF Kitchen Cabinets | Plywood Kitchen Cabinets | Solid Wood Cabinets |

Material | Wood fibers + resin | Thin wood veneers | Natural hardwood |

Durability | Moderate | High | Very high |

Moisture Resistance | Medium | High | High |

Finish Quality | Smooth and uniform | Visible natural grain | Natural texture |

Ideal For | Painted modern kitchens | Versatile use | Premium projects |

In summary:

MDF is best for developers seeking smooth painted finishes at a lower cost, while plywood performs better in moisture-prone environments.

MDF’s smooth surface can be finished in a variety of ways to achieve different looks and performance levels. Developers can select from several finish options based on project requirements and budget.

Popular MDF cabinet finishes include:

Paint Finish: Smooth and contemporary; ideal for white or pastel kitchens.

Lacquer Finish: Provides a glossy, high-end appearance, commonly used in luxury kitchens.

PVC/PET Laminate: Adds moisture resistance and mimics wood grains or matte textures.

Veneer Finish: Combines MDF’s stability with the warmth of real wood veneer.

These finishes give builders flexibility to meet diverse market demands — from economy apartments to high-rise residential projects.

Cost-Effective for Bulk Orders - MDF significantly reduces material costs for developers working on multi-unit housing or apartment projects.

Excellent Paint Absorption - The fine fibers hold paint evenly, resulting in smooth, premium-looking surfaces.

Smooth, Flat Surface - Perfect for contemporary and minimalist designs that require a flawless finish.

Eco-Friendly Options - Many modern MDF boards are made with recycled wood fibers and low-formaldehyde adhesives.

Easy Machining and Customization - MDF can be precisely cut and shaped by CNC machines, ensuring consistency across large production runs.

Moisture Sensitivity - MDF is not naturally water-resistant. It should be sealed or laminated for kitchens exposed to humidity.

Lower Structural Strength - It’s not as strong as plywood for load-bearing carcasses or heavy wall cabinets.

Heavier Weight - Because of its density, MDF panels are heavier, which may slightly increase shipping or installation costs.

Developer Tip - Combine MDF door panels with plywood cabinet boxes to achieve both aesthetic appeal and structural stability — a common solution for large-scale apartment projects.

MDF cabinets are widely used in:

Apartment kitchens

Hotel kitchenettes

Student housing

Multi-family developments

Commercial rental units

For developers and contractors, MDF offers:

Consistent surface quality across units

Flexible color matching for different layouts

Simplified repair and replacement process

Shorter production lead times and lower material waste

Its adaptability makes MDF a smart material for fast-moving housing developments and turnkey interior projects.

MDF kitchen cabinets typically cost 20–40% less than plywood ones, depending on design, finish, and hardware quality.

For developers ordering in bulk, prices can be further reduced through standardized production templates and optimized cutting processes.

Cost Efficiency Example:

Plywood kitchen cabinets: $250–$350 per linear meter

MDF kitchen cabinets: $150–$250 per linear meter

The savings become significant when multiplied across dozens or hundreds of units.

To keep MDF kitchen cabinets in top condition:

Avoid prolonged contact with water or steam.

Clean regularly using a soft, damp cloth (no harsh chemicals).

Repaint or re-laminate when the surface becomes dull.

Install soft-close hinges and drawer slides to minimize stress on the panels.

With proper care, MDF cabinets can last for many years while maintaining their appearance.

MDF kitchen cabinets are a cost-effective, versatile, and visually appealing choice for developers and builders handling large-scale residential or commercial projects.

When finished with quality paint or lamination and paired with durable hardware, MDF offers both aesthetic excellence and reliable performance.

For developers seeking an ideal balance between budget and design, MDF remains one of the best cabinetry materials for modern kitchens — combining the look of luxury with the practicality of large-scale production.

1. Are MDF kitchen cabinets durable enough for large projects?

Yes. MDF kitchen cabinets are durable for most residential and commercial kitchens when properly sealed and installed.

While MDF is not as moisture-resistant as plywood, its dense core and smooth surface make it ideal for interior cabinet doors and panels, especially in dry or climate-controlled environments.

2. Are MDF cabinets waterproof?

No, standard MDF is not waterproof. However, moisture-resistant MDF (MR MDF) is available and is a better choice for kitchens and bathrooms.

To improve longevity, always use edge banding, waterproof finishes, or laminates on exposed areas.

3. Is MDF cheaper than plywood or solid wood?

Yes. MDF kitchen cabinets are typically 20–40% less expensive than plywood, and much cheaper than solid wood.

That’s why developers and builders often use MDF for large-scale apartment or hotel projects where consistent finishes and cost control are essential.

4. Can MDF kitchen cabinets be painted or customized?

Absolutely. MDF’s smooth and uniform texture makes it perfect for painting, lacquering, or lamination.

Developers can choose any color, gloss level, or surface style — from matte minimalist designs to high-gloss modern kitchens.

When properly maintained, MDF cabinets can last 10–15 years or more.

The key is to protect them from excess moisture and use high-quality hardware for daily functionality.

6. What’s the best cabinet structure for large projects using MDF?

For the best balance of cost and strength, many manufacturers recommend:

MDF doors + Plywood carcasses.

This combination delivers the smooth surface of MDF doors with the strong, moisture-resistant structure of plywood boxes.

7. Are MDF kitchen cabinets eco-friendly?

Yes — modern MDF boards are often made from recycled wood fibers and low-formaldehyde adhesives, making them a sustainable option for large-scale developments that follow green building standards.

8. What finish is best for MDF cabinets in modern apartments?

For modern apartment projects, matte or semi-gloss lacquer finishes are ideal.

They provide a clean, premium look and are easier to maintain than high-gloss finishes in heavy-use environments.

9. Can MDF cabinets handle bulk production for developers?

Yes. MDF is highly consistent and machine-friendly, making it perfect for mass production.

It ensures uniform quality across hundreds of units — a major advantage for developers managing multi-apartment or hotel projects.

10. Who should I contact for MDF kitchen cabinet manufacturing?

For developers and contractors seeking custom MDF kitchen cabinet production,

AIS HOME GROUP offers end-to-end service — from 2D layout design and 3D visualization to manufacturing, packaging, and global shipping.