Total Cabinetry And Joinery Solution

ENG

Wood Veneer Kitchen Cabinets are back in the design spotlight for 2026. They offer the warmth and richness of real wood, but with a slimmer profile, better dimensional stability, and often a more friendly price point than full solid wood. For homeowners, designers, and developers working on large-scale projects, veneer has become a go-to choice to achieve a high-end look without blowing the budget.

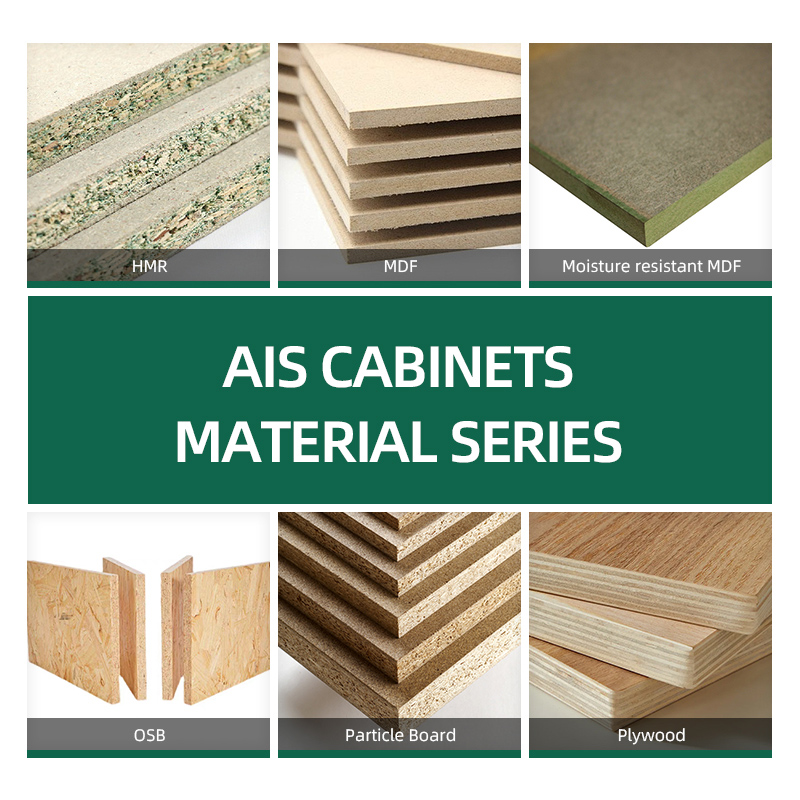

Wood veneer is a thin slice of real hardwood bonded to a core panel such as MDF, particleboard, or plywood. This construction is what defines Wood Veneer Kitchen Cabinets:

Surface: Genuine wood grain (oak, walnut, ash, etc.).

Core: Engineered board (MDF/particleboard/plywood) for stability and cost control.

Finish: Stain, clear lacquer, or paint, just like solid wood.

This structure delivers the look of solid wood at a lower cost, with more predictable performance, because the engineered core is less prone to warping and movement than thick solid lumber.

Natural beauty meets modern minimalism

2026 kitchen trends continue to favor:

Clean lines and slab doors

Simple, handle-less fronts

Calm, natural materials

Wood Veneer Kitchen Cabinets are ideal here: they provide continuous, book-matched or sequence-matched grain across tall doors and long runs of cabinets, something that’s harder and more expensive to achieve with solid wood boards.

You get:

Warm, natural wood tones instead of “fake wood” prints

Sleek, modern silhouettes that work with contemporary appliances

The ability to dial the style from Scandinavian light tones to deep, luxurious walnut

More sustainable use of timber

Veneer is a resource-efficient way to use real wood. Instead of cutting thick boards, manufacturers slice logs into thin sheets, dramatically increasing the surface area that one tree can cover. That means:

Less waste of premium species like walnut or oak

More projects can enjoy real wood without needing as much raw timber

This efficiency is one reason many architects and designers see wood veneer as a more sustainable option than full solid wood panels, especially on large projects.

Cost-effective “luxury look”

From a cost perspective, Wood Veneer Kitchen Cabinets sit between solid wood and laminates:

More affordable than solid wood because the expensive hardwood is used only as a thin surface layer.

More premium-looking than plastic laminates, which can sometimes feel artificial.

For developers or builders outfitting multiple units (apartments, condos, villas), this mid-range price bracket is extremely attractive: you get a high-end appearance with controlled costs.

While you can veneer almost any species, a few are especially popular for 2026:

Light oak veneer

Soft beige and sand tones

Subtle grain, perfect for Scandinavian or Japandi kitchens

Works beautifully with white countertops and matte black hardware

Walnut veneer

Rich, chocolate-brown tones with striking grain

Instantly luxurious, ideal for high-end villas and penthouses

Pairs well with brass or champagne-gold hardware and stone benchtops

Ash and maple veneer

Light, often slightly warm or greyish tones

Smooth grain that reads very “clean” in modern designs

Great for small kitchens because they reflect more light

Rift-cut / quarter-sawn veneer for vertical grain

Engineered veneer layups can create perfectly straight, vertical grain across multiple doors. This looks incredibly modern and helps visually “stretch” the kitchen height, especially on tall pantry and integrated fridge doors.

Here are some practical ways to design with Wood Veneer Kitchen Cabinets in 2026:

Two-tone: veneer base cabinets + painted uppers

Use wood veneer on base cabinets and tall units for warmth and texture.

Keep upper cabinets or wall panels in white, cream, or soft grey to avoid visual heaviness.

This combination offers both contrast and balance and works in open-plan living areas.

Full-height veneer wall with integrated appliances

Create a floor-to-ceiling veneer wall with tall cabinets.

Integrate fridge, ovens, pantry, and even hidden doors behind continuous veneer fronts.

The result is a clean architectural statement where appliances “disappear” into the wood.

Island as a wood feature

Use wood veneer just on the kitchen island while keeping perimeter cabinets in a neutral color.

Add a waterfall countertop to highlight the island as a focal point.

Perfect for social kitchens where the island is the main gathering spot.

Mixed textures: veneer + stone + metal

Combine veneer cabinets with veined quartz or sintered stone countertops.

Add metal accents (handles, toe-kicks, open shelves, or framing) in black, brushed nickel, or brass.

This layering of textures gives a high-end, hotel-style feel.

Durability in daily use

Well-made Wood Veneer Kitchen Cabinets are designed for daily kitchen life. Key points:

Veneer is bonded to stable cores like MDF or plywood, making it less prone to warping and cracking than solid wood in changing humidity.

The surface is still real wood, so it can scratch or dent if mistreated, similar to solid wood.

However, because veneer is thin, deep sanding and heavy refinishing are limited: you can’t sand it as aggressively as solid wood without cutting through the veneer layer.

Moisture resistance

Moisture is a key concern in kitchens:

Properly sealed veneer and edges can perform very well, but unsealed edges or long-term water exposure can cause peeling or damage, just like with many other wood products.

Higher-quality phenolic-backed veneers and moisture-resistant cores add extra protection.

Simple best practices:

Wipe spills quickly, especially around sink and dishwasher.

Avoid soaking the cabinet fronts with harsh chemicals or steam.

Ensure your installer seals cut edges and joins properly.

Lifespan and maintenance

With good installation and care, wood veneer cabinets can last 15–20 years or more in normal residential use.

Day-to-day care is simple:

Dust with a soft cloth

Clean with mild soap and water

Avoid abrasive pads and aggressive cleaners

Feature | Wood Veneer Kitchen Cabinets | Solid Wood Cabinets | Laminate Cabinets |

Surface material | Thin layer of real wood on engineered core | Solid natural wood | Printed décor layer on synthetic core |

Look & feel | Very natural, consistent grain | Rich, unique grain and character | Can mimic wood, but less authentic |

Cost | Mid-range | Highest | Often lowest |

Dimensional stability | More stable than solid wood | Can expand/contract with humidity | Very stable |

Durability & repair | Good; limited sanding/refinishing possible | Excellent; can be fully sanded and refinished | Good surface durability; hard to repair if chipped |

Sustainability | Efficient use of hardwood | Renewable but uses more raw timber | Made with synthetic materials |

Design flexibility | Excellent for large, matched-grain panels | Best for detailed profiles, frames, and panels | Huge color/pattern range, including non-wood looks |

For many 2026 projects, veneer hits the sweet spot: more premium than laminate, more budget-friendly and stable than full solid wood, especially on large, flat doors.

When you’re choosing Wood Veneer Kitchen Cabinets with a supplier or manufacturer, pay attention to:

Core material

MDF: very smooth, ideal for flat, painted or stained veneer fronts.

Plywood: strong and moisture-resistant, good for carcasses and high-humidity areas.

Veneer type & backing

Species: oak, walnut, ash, maple, etc.

Cut: plain-sawn, quarter-sawn, rift-cut for different grain patterns.

Backing: paper-backed vs phenolic-backed (more moisture-resistant).

Matching method

Book-matched or sequence-matched veneer for continuous grain across doors.

Random-matched for a more rustic, organic look.

Finish system

Clear matte or satin lacquer for a modern, natural look.

Stained finishes to warm or cool the tone.

Check if the finish is scratch-resistant and UV-resistant to reduce fading.

Edge treatment

Veneer-wrapped edges or color-matched PVC edge banding.

Clean edges are crucial for both look and durability.

Hardware and details

Soft-close hinges and drawers.

Handle-less systems (J-pull, Gola profile, push-to-open) for a super-minimal look.

Integrated LED lighting under wall cabinets or in glass units.

Certifications & emissions

Ask for CARB/EPA or E0/E1 formaldehyde emission ratings on core boards.

This ensures healthier indoor air quality, especially in tight, modern homes.

Wood Veneer Kitchen Cabinets are an excellent fit if you:

Want real wood beauty without solid-wood pricing.

Like minimalist, continuous-grain designs with tall doors and clean lines.

Need stable, predictable performance for modern HVAC-controlled homes or multi-unit projects.

Care about sustainable material use and efficient use of hardwood resources.

They may not be ideal if you:

Expect to sand and refinish cabinets multiple times over decades, like vintage solid wood.

Prefer ultra-rugged, “no-worry” synthetic finishes for very high-traffic rental kitchens.

For 2026, however, Wood Veneer Kitchen Cabinets sit perfectly at the intersection of style, sustainability, and smart budgeting—making them one of the most attractive options for both private homes and professional developments.

1. Who is the largest kitchen cabinet manufacturer in North America in 2026?

Among all North American Kitchen Cabinet Makers, industry research identifies MasterBrand as the largest by market share. With its planned merger with American Woodmark, the combined entity will further strengthen its leadership position in the North American Kitchen Cabinet Makers landscape.

2. What’s the difference between big cabinet groups and smaller regional makers?

Within the world of North American Kitchen Cabinet Makers, large groups like MasterBrand, American Woodmark, and Cabinetworks offer huge capacity, many brands, and national programs—ideal for big developers. Smaller regional North American Kitchen Cabinet Makers (e.g., Cabico, AyA, Superior, Crystal) often provide more design flexibility and closer service, which is valuable for higher-end or design-driven projects.

3. Are Canadian kitchen cabinet manufacturers competitive with U.S. brands?

Yes. Canadian North American Kitchen Cabinet Makers such as Cabico, AyA Kitchens & Baths, and Superior Cabinets are recognized as leading cabinet manufacturers, combining high craftsmanship with modern styles and strong regional networks, particularly for projects across Canada and parts of the northern U.S. They compete directly with U.S.-based North American Kitchen Cabinet Makers on both design and quality.

4. What cabinet construction do most North American manufacturers use?

Most North American Kitchen Cabinet Makers offer framed cabinets (very common in the U.S.) plus increasingly popular frameless / European lines. Semi-custom framed cabinets remain the dominant construction in mid-market projects, while frameless options from many North American Kitchen Cabinet Makers are favored for contemporary, urban, and higher-end designs.

5. Are semi-custom cabinets enough for multi-family projects?

For most apartments, townhomes, and standard single-family units, semi-custom cabinets from reputable North American Kitchen Cabinet Makers provide more than enough flexibility—different widths, heights, interior accessories, and finish options—without the cost of full custom. Custom cabinetry from specialized North American Kitchen Cabinet Makers becomes more relevant for luxury units, penthouses, and highly irregular layouts.

6. How important is sustainability when choosing a cabinet manufacturer?

Sustainability is becoming a key selection factor when comparing North American Kitchen Cabinet Makers. Many manufacturers now highlight low-VOC finishes, CARB/TSCA compliance, and sustainable sourcing to meet stricter regulations and ESG requirements on large projects. When shortlisting North American Kitchen Cabinet Makers, checking certifications and environmental statements is strongly recommended.

7. Do North American cabinet makers support large developer or hotel projects?

Yes—especially the larger North American Kitchen Cabinet Makers such as MasterBrand, American Woodmark, Cabinetworks, and Wellborn, as well as some Canadian manufacturers. They often run dedicated builder, multi-family, or commercial programs, including dedicated account managers, standard spec packages, and logistics support tailored to large developer and hotel projects.

8. Are North American cabinets more expensive than imported cabinets?

Generally, cabinets produced by North American Kitchen Cabinet Makers carry higher labor and material costs than many imported options, but they offer advantages like shorter lead times, easier warranty claims, and “Made in USA/Canada” value. Many projects combine both—using North American Kitchen Cabinet Makers for flagship units and imported lines for secondary or bulk units.

9. How do I compare quality between different cabinet brands?

When comparing different North American Kitchen Cabinet Makers, look closely at:

Box construction (plywood vs. particleboard, back panel thickness)

Hardware (soft-close hinges/slides from reputable brands)

Finish quality (evenness, durability, stain resistance)

Certifications and reviews (industry associations, independent ratings, dealer feedback)

These criteria help you benchmark North American Kitchen Cabinet Makers on real, measurable quality.

10. Which North American cabinet makers are best for modern, minimalist kitchens?

For clean, modern, or European-style projects, focus on North American Kitchen Cabinet Makers such as AyA Kitchens, Cabico, Superior Cabinets, Fabuwood, and select frameless lines from MasterBrand and Cabinetworks. These North American Kitchen Cabinet Makers offer flat-panel doors, integrated handles, and contemporary finishes suited to 2026 design trends.