MDF vs Plywood: Which Is Better for Kitchen Cabinets?

In modern kitchen design, island kitchen cabinets have become an essential feature, blending functionality, aesthetics, and lifestyle needs. More than just a visual centerpiece, the kitchen island serves as a multi-purpose hub that enhances the way we cook, gather, and live.

But beyond layout, one of the most critical decisions in building or renovating your kitchen is the choice of cabinet material—and this is where MDF and Plywood often come into comparison. Both materials are widely used, but they serve different purposes depending on your design goals, budget, and durability requirements.

In this article, we’ll break down the advantages and disadvantages of MDF vs Plywood, helping you make an informed decision for your kitchen.

What is MDF?

MDF (Medium-Density Fiberboard) is an engineered panel made by compressing wood fibers with wax and resin under heat and pressure. It offers a perfectly smooth, grain-free surface that machines cleanly and takes paint or lacquer beautifully, and it’s cost-effective for decorative fronts and wall panels. Because of that uniform texture, MDF is a popular choice for cabinet doors and drawer fronts.

That said, MDF is not water-resistant—it can swell or warp with prolonged moisture. For wet or high-load zones (e.g., sink bases, laundry, carcasses), plywood—built from cross-laminated veneers—usually performs better thanks to stronger screw holding, higher stiffness, and improved moisture tolerance (still not waterproof, but more resilient than standard MDF).

Quick takeaways (MDF vs plywood):

1、Finish: MDF = ultra-smooth for paintaed/lacquered finishes; plywood shows wood grain/plies.

2、Strength & fasteners: Plywood holds screws and spans loads better; MDF is denser but less screw-friendly at edges.

3、Moisture: Standard MDF dislikes humidity; plywood handles it better. Moisture-resistant MDF grades help, but are not waterproof.

4、Best use: MDF for paint-grade doors, drawer fronts, decorative panels; plywood for cabinet boxes, sink bases, utility areas.

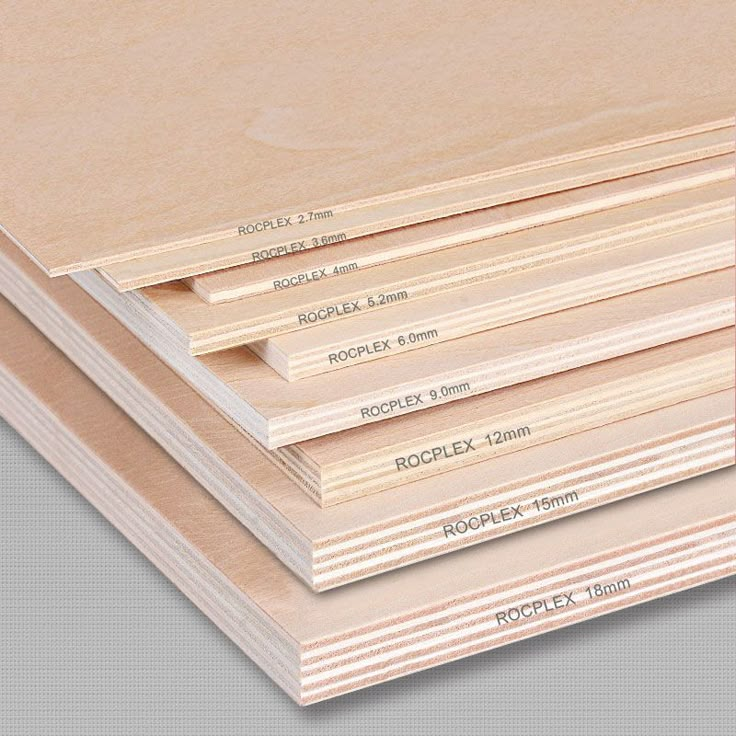

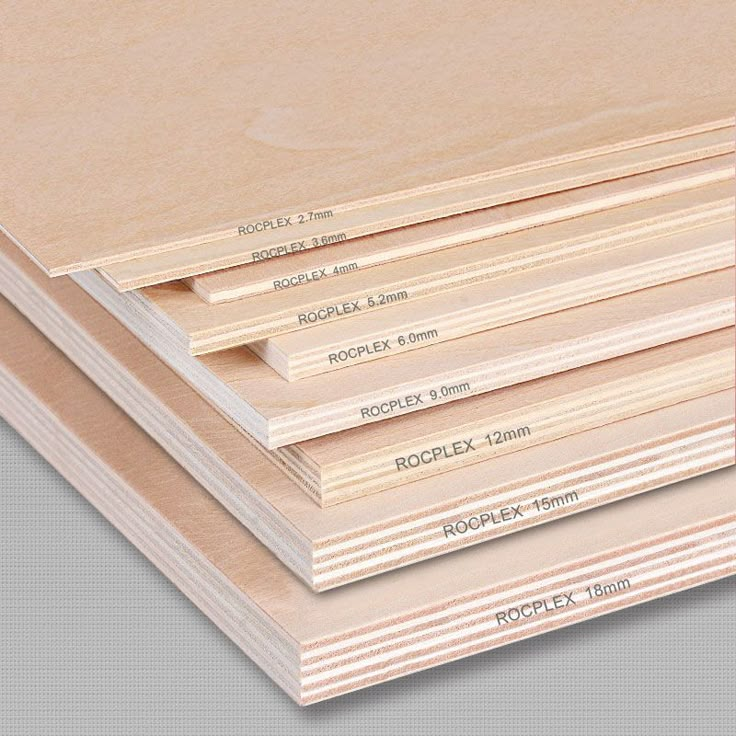

What is Plywood?

Plywood is built from thin wood veneers (plies) bonded with the grain of each layer set crosswise to the previous one. This cross-lamination creates panels that are strong, dimensionally stable, and resistant to splitting—ideal for cabinetry.

Key advantages (plywood vs MDF):

1、Strength & weight: Higher strength-to-weight and better racking resistance than MDF, so it’s great for cabinet carcasses, drawer boxes, and shelving.

2、Moisture tolerance: Handles humidity better than MDF. For wet zones (sink bases, near dishwashers) choose HMR or marine-grade plywood; still seal edges—plywood isn’t fully waterproof.

3、Fastener holding: Superior screw holding in faces and edges, keeping hinges and slides tight over time.

4、Natural look: Visible wood grain accepts stain or veneer beautifully; also works under clear coats for a warm, authentic finish.

When to choose plywood

Carcasses/boxes & shelves in high-use or moisture-prone zones (kitchens, baths, laundry). Plywood is stiffer per weight, resists sag better than MDF, and has superior screw-holding for hinges, slides, and pocket-holes.

Durability & transport: Lighter than MDF, less likely to blow-out at corners, and holds up better to jobsite handling.

Moisture: Exterior-glue or marine/HPL-faced plywood tolerates humidity swings and minor spills; edges still need sealing.

Pro tips:

Specify calibrated, void-free cores (e.g., birch/poplar multi-ply) and 2 mm edge-banding for a premium look.

Use downcut/Compression bits to minimize veneer tear-out; prefinished maple/birch saves finishing time.

For long shelves, plywood spans farther; add a front edge strip to increase stiffness.

When to choose MDF

Paint-grade doors/drawer fronts and profiled millwork (Shaker rails, routed panels, ogees). MDF machines crisp, ripple-free edges and paints to a glass-smooth finish without telegraphing grain.

Flatness & consistency: Excellent for wide panels that must be dead flat (wall panels, tall doors) in dry, conditioned interiors.

Cost & availability: Often cheaper and easy to source in large sheets.

Pro tips:

Use moisture-resistant (MR/HMR) MDF in kitchens/baths; still seal all edges, especially sink runs.

MDF is heavy and has weaker screw-holding—prefer Euro screws + large pilot holes, or use inserts; avoid over-tightening.

Prime all cut edges (shellac/sanding sealer), sand 220–320, then top-coat for a flawless paint finish.

MDF vs Plywood: Feature Comparison

| Feature | MDF | Plywood |

|---|

| Strength | Medium | High |

| Water Resistance | Low | High |

| Price | Lower | Higher |

| Paint Finish | Excellent (smooth and flawless) | Good (may show grain unless sanded) |

| Weight | Heavier | Lighter |

| Ease of Cutting | Easy | Requires proper tools |

| Sustainability | Often contains more recycled material | Depends on wood source |

Which One Should You Choose?

The choice between MDF and Plywood depends on where and how the material will be used.

Choose MDF if you:

1、Want a smooth, modern painted finish

2、Need a cost-effective option for doors, panels, or decorative elements

3、Are not concerned about moisture exposure

Choose Plywood if you:

1、Need strong, durable materials for cabinet boxes or shelves

2、Expect the area to be exposed to water or humidity

3、Prefer a more natural or veneered wood appearance

In many high-end kitchens, manufacturers use a combination of both:

1、MDF for cabinet doors (especially if painted)

2、Plywood for cabinet interiors and structural parts

Conclusion

There’s no one-size-fits-all answer to the MDF vs Plywood debate. Both materials have their strengths and limitations. The best approach is to match the material to its purpose in your kitchen:

1、Go with MDF for design flexibility and smooth finishes.

2、Choose Plywood for structural reliability and moisture resistance.

Ultimately, your decision should consider not just cost, but also performance, appearance, and longevity—especially in a space as hardworking as the kitchen.

FAQ:

1. What is the main difference between MDF and plywood for kitchen cabinets?

MDF (medium-density fiberboard) is made from wood fibers and resin, pressed into a dense, smooth board. Plywood is made from thin wood veneers glued in layers with alternating grain directions. In practice, MDF is smoother and better for detailed profiles and paint, while plywood is lighter, stronger in structure, and has a more “natural wood” feel.

2. Which is stronger and more durable for kitchen cabinet boxes, MDF or plywood?

For cabinet boxes and shelves, plywood is generally stronger and more resistant to sagging over long spans. Its cross-laminated layers give it better screw-holding strength and impact resistance. MDF can still be durable when used correctly, but it is heavier and more prone to damage at fasteners and corners compared with quality plywood.

3. Which material is better for cabinet doors and painted finishes?

MDF is usually better for painted cabinet doors. The surface is very smooth, with no wood grain or voids, so it takes paint evenly and allows crisp shaker profiles and routed details. Plywood doors can show grain or small imperfections, and may require more sanding and filling if you want a perfectly smooth, modern painted finish.

4. Are MDF kitchen cabinets cheaper than plywood?

Yes, MDF is typically more budget-friendly than high-quality plywood. For cost-sensitive projects, MDF doors combined with particle board or MDF boxes can significantly reduce the overall price. Plywood, especially moisture-resistant or furniture-grade plywood, usually costs more but offers a higher perceived value and better structural performance.

5. How do MDF and plywood handle moisture and humidity in a kitchen?

Standard MDF can swell, soften, or warp if exposed to standing water or high moisture for long periods. Plywood performs better in humid environments and is less likely to swell, especially if you use moisture-resistant or marine-grade options. However, any cabinet material needs proper edge sealing, waterproof countertops, and good ventilation to avoid damage.

6. Which is better for heavy-duty use and long-term durability?

For heavy-duty use—like busy family kitchens, rental properties, or high-traffic commercial projects—plywood is often the safer choice for cabinet boxes and shelves. It holds screws more securely and resists impacts and rough use better than MDF. MDF can still last many years if it’s properly supported, sealed, and not exposed to moisture or abuse.

7. Are MDF and plywood environmentally friendly and safe (formaldehyde, VOCs)?

Both MDF and plywood can be made with low-emission, CARB-compliant or E0/E1 standard resins. Always check the certification and emission class from your cabinet supplier. If indoor air quality is a priority, choose materials with formaldehyde-free or ultra-low VOC labels and ask for documentation from the manufacturer.

8. Can I mix MDF and plywood in the same kitchen cabinet design?

Yes, mixing materials is very common and can balance cost and performance. A popular combination is: plywood for cabinet boxes and shelves (for strength and screw-holding) and MDF for doors and decorative panels (for smooth painted finishes). This hybrid approach often gives the best overall value.

9. Which material is better for DIY installation, MDF or plywood?

Plywood is lighter and handles screws better, which makes it more forgiving for DIY installation. MDF is heavier and can split or crumble if screws are over-tightened or too close to the edge. If you’re installing MDF cabinets yourself, pre-drill screw holes, support panels carefully, and avoid over-driving screws.