Total Cabinetry And Joinery Solution

ENG

Australia is one of the world’s most quality-conscious markets when it comes to home furnishings — and kitchen cabinets are no exception. Strict building codes, sustainability expectations, and consumer safety regulations shape what products can enter and thrive in the Australian market.

If you're a manufacturer or exporter aiming to sell kitchen cabinets to Australia, it’s essential to understand and meet the key standards to ensure smooth customs clearance, secure long-term partnerships, and avoid costly returns or project rejections.

The most critical standard is:

AS/NZS 4386.1:1996 — This is the Australian/New Zealand standard that covers the design and construction of domestic kitchen units.

Key requirements include:

Cabinets must be structurally sound and durable under normal use.

Hinges, runners, and shelf supports must meet specified load-bearing capacity.

Shelving and drawer strength must withstand minimum weight and impact.

🔎 Tip: Request third-party lab testing and provide documentation during export.

Due to Australia’s humid and coastal climate, moisture resistance is critical.

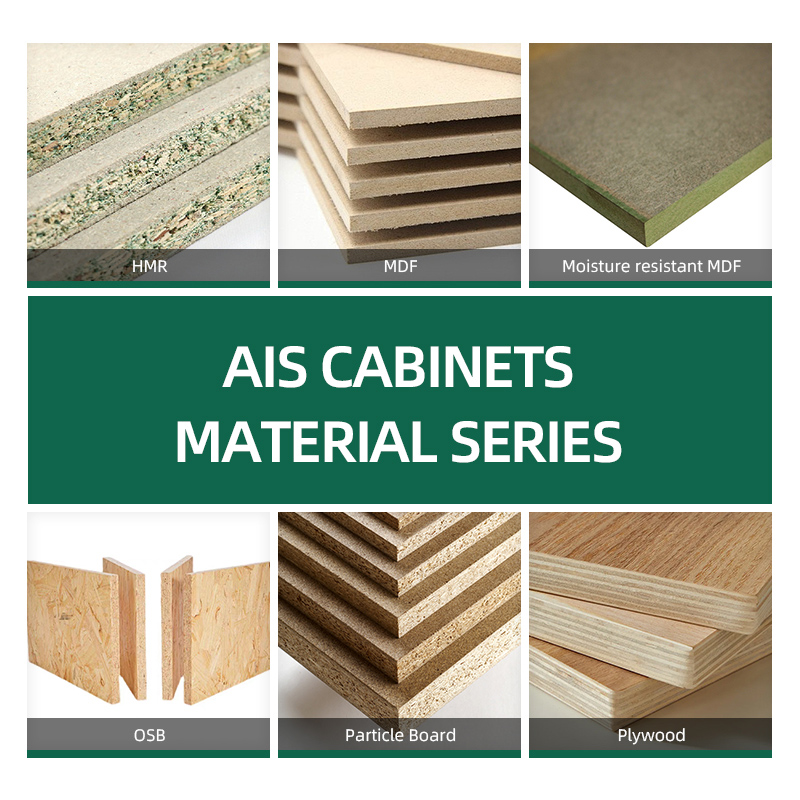

HMR MDF (High Moisture Resistance Medium-Density Fiberboard) is preferred for cabinet carcasses and door panels.

Edges must be properly sealed to prevent swelling or delamination.

Sink cabinets, in particular, require extra sealing or protective lining.

🔎 Tip: Label your material specifications clearly (e.g., “HMR core with melamine surface”).

Australian consumers are highly aware of indoor air quality and environmental impacts. The following certifications are often expected (though not always legally required):

E0 or E1 Formaldehyde Emission Rating (lower is better) — align with Australian standards for indoor air.

FSC® or PEFC™ Certification — if wood or wood-based panels are used, sustainability certification boosts trust.

Low-VOC Paint and Lacquer — for painted cabinets, ensure coatings meet VOC limits.

🔎 Tip: Provide MSDS (Material Safety Data Sheet) for paint, glue, and finishes.

For commercial applications, some Australian states require:

Fire-rated boards or fire-retardant coatings (especially in high-rise apartments and hotels).

Compliance with AS 1530.3, the standard test for combustibility of materials.

For residential low-rise homes, standard melamine/HMR boards are acceptable unless specified otherwise.

Imported hinges, drawer slides, and lift systems must demonstrate:

Durability under cyclic testing

Resistance to rust/corrosion (especially in coastal regions)

Soft-close or push-open mechanisms are often required in mid-to-high-end projects

🔎 Tip: European or BLUM-style hardware is widely accepted and respected in the Australian market.

To comply with Australian Customs & Biosecurity, exporters must:

Use ISPM 15 certified wood pallets (heat-treated or fumigated)

Avoid materials like hay, straw, or untreated wood packaging

Label all cartons in English with dimensions, weight, and content

Documents you must provide:

Commercial Invoice

Packing List

Certificate of Origin (preferably under China-Australia Free Trade Agreement – ChAFTA)

Bill of Lading

Compliance or test certificates (AS/NZS, emissions, etc.)

❌ Using non-moisture-resistant MDF in wet areas

❌ Failing to provide formaldehyde emission certification

❌ Packaging materials flagged by Australian Quarantine and Inspection Service (AQIS)

❌ Overlooking minor labeling inconsistencies (can cause shipment holds)

Partner with local importers or developers who understand local code

Offer 3rd-party certification for large or government projects

Use Australian terminology in your design communication (e.g., “laminate benchtop” instead of “countertop”)

Create clear installation manuals in English

Meeting Australian standards isn’t just a legal checkbox — it’s a gateway to trust, repeat orders, and long-term success. Kitchen cabinets that combine moisture resistance, eco-friendly materials, and durability will thrive in this discerning market.

Exporters who go beyond the minimum and proactively address compliance will stand out as premium, professional, and reliable partners.